silk-screen printing (serigraphy) In printing, a means of producing a print, generally on paper. A screen composed of a mesh of silk or man-made fibers is stretched over a wooden frame; a design is ‘stopped out’ (painted) on the mesh, using glue, varnish, gelatin, or a paper stencil. To make the print, ink is taken across the screen with a squeegee; the pressure of this pushes the ink through the unstopped areas of the mesh. Several screens may be used to build up a multi-colored print. *source: encyclopedia.com

Now you know what screen printing is, but why should you consider it for your company’s printing needs?

- Screened prints are Very durable compared to many digital options which may not hold up as well or as long

- Greater range of materials/substrates – You can screen print materials that some digital printers cannot, including wood, plastics, glass, and metals.

- Value, especially with volume – Screen Printing has a bit more setup, but once the negatives are ready they can be used over and over to produce more prints

- Vibrant Colors – While it is true that Digital has come a long way, the true brilliance of screen printed inks is still truly impressive and hard to replicate. Ink has much denser coverage compared to digital prints

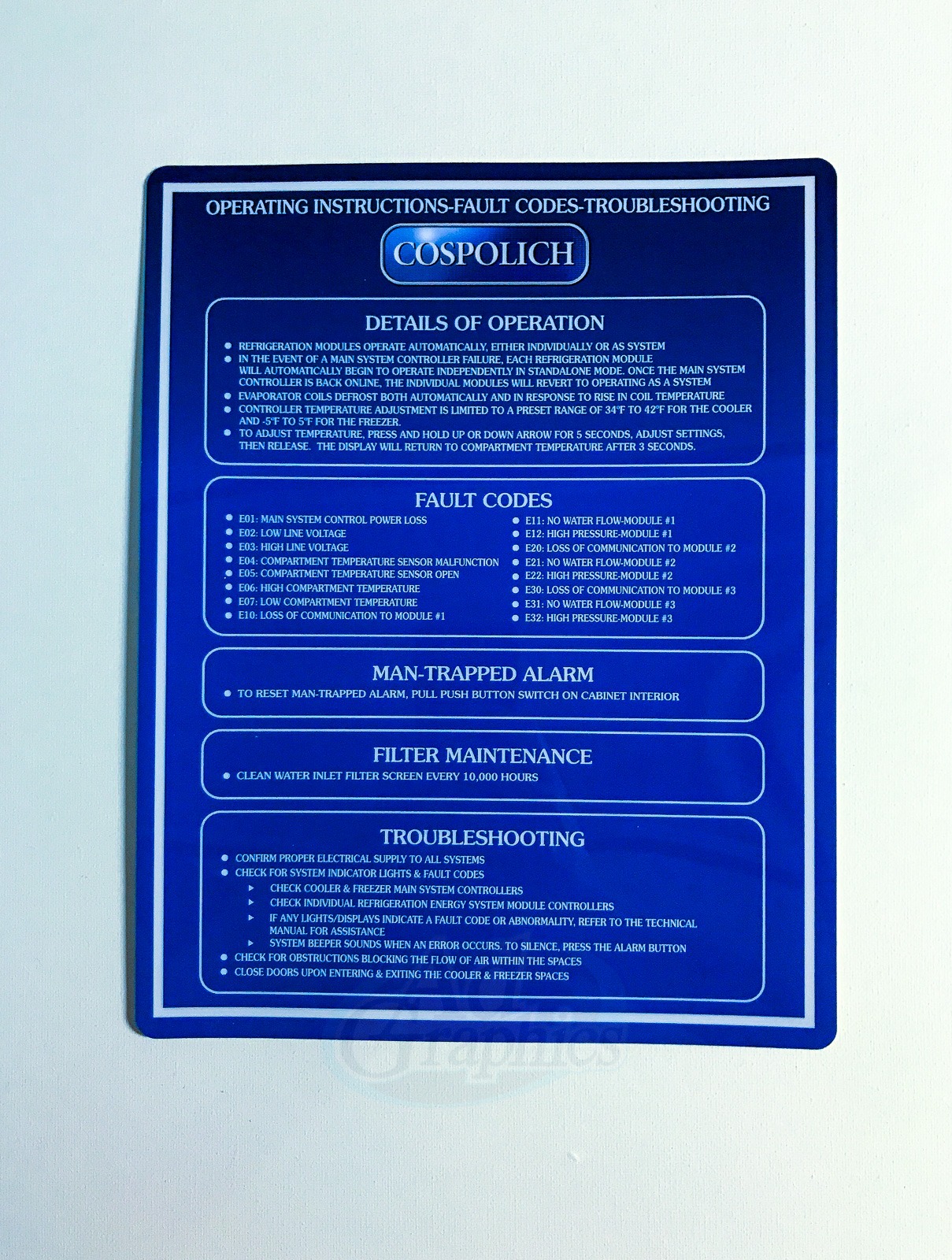

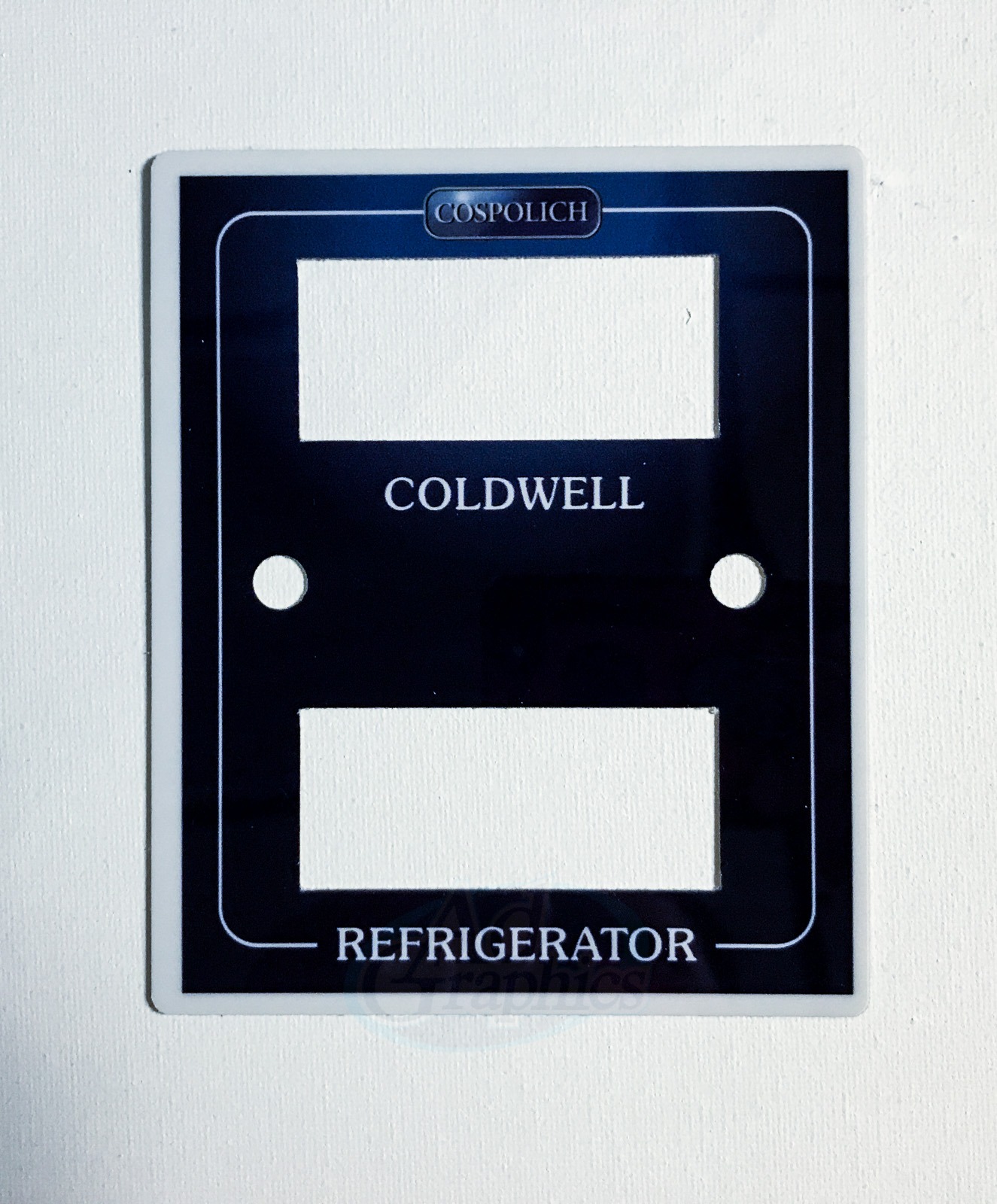

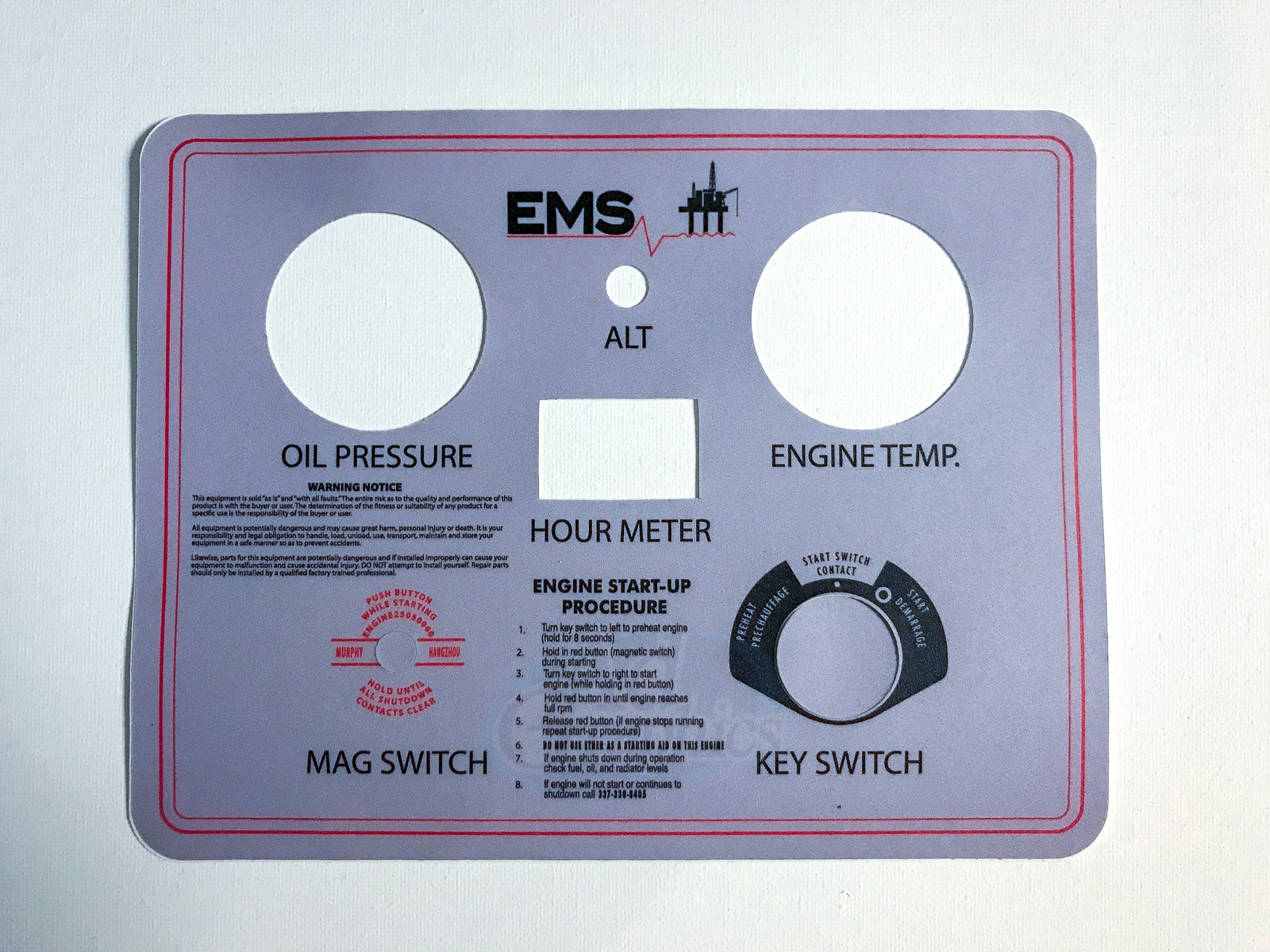

Let’s say Dangerous Chemicals, Inc. (DCI) is looking for a Sign Shop near Metairie to produce some control panels for their equipment and logo decals for their hard hats. Ad Graphics has a wide range of materials appropriate for just such applications. Our Graphic Designers will prepare art for production or create new art as needed. Once ready, our Screen Printer will produce the DCI logos on a ControlCal decal that will conform to the hard hats so they look professional. He will then mirror-print Lexan sheets with DCI’s control panels, die cut them so they fit the machines properly, emboss the buttons so they are easy to recognize and index, and apply an adhesive film so they can be firmly applied to the machine. Does this sound like your company? Give our sales team a call today to find out how to get started.